Location of Pipeline Ruptures using

ECOPROBE 5

ECOPROBE 5 instruments have been used for many pipeline rupture assessments, where petroleum hydrocarbon products were leaking into the ground. Using ECOPROBE 5 for hydrocarbon leakage detection along the pipeline route is remarkably fast and convenient. Leaking pipelines usually cause large fresh hydrocarbon contaminations, which give out huge amounts of hydrocarbon vapors, easily detectable on the surface without the necessity of making sampling holes into the ground. It is possible just to use a stainless-steel bell connected to the probe. The bell is placed at each measured station on the ground surface and after a short required time (30 seconds) the measurement can be continued. In this way the measurement at each station takes about 1 minute and the operator can move very quickly along the pipeline route with each recommended step from the measured station of 5 (maximum 10 ) meters. About 30 stations can be measured within an hour: this means 240 stations in 8 working hours which represents approximately 1200 – 2400 meters of the surveyed pipeline route, conveniently using GPS logging. Fresh pipeline leakage contamination is characterized by no Methane readings (bacterial activity has not yet started). Large pipeline contaminations are most common, very easily detectable by the Infra-Red Total Petroleum channel. Small ruptures and leakages or deep contaminations are detectable by PID analyzer, providing identification of even minimal contamination levels.

Study Site

An estimated 110 000 liters of diesel fuel and some petrol escaped from a ruptured product line located 2 meters below the surface alongside a major throughway. The pollution plume enclosed a planned shopping complex, a telecommunication cable and the storm water drainage system for the surrounding area. On the opposite side of the main road, a residential area relies on a shallow aquifer for supplying water for gardening. The contaminated area was situated in unconsolidated coastal sediments comprising medium-grained topsoil overlying a 0.5 meter thick clay layer with a water table about 1 meter below the surface. Free products – the diesel fuel and petrol – were floating on the upper water table. The pipeline rupture area was found by ECOPROBE 5 using the above mentioned technique some weeks after the incident. The position of the pollution plume was delineated with ECOPROBE 5 and confined to the east side of the highway. Very weak signals on PID channel indicated a contamination front also west of the highway. Further from the recent contamination, higher values of Methane were indicated on Methane channel, signaling long-standing contamination. The residents were interviewed in an attempt to solve the problem. It was established that 15 years previously, the same pipeline cluster had developed a leak about 80 meters from the present site. ECOPROBE 5 supported not only a cost effective initial site assessment, but was widely used for the follow up monitoring of plume migration and testing the results of site cleaning.

Ten months later a second soil vapor survey was commissioned to determine if the plume had migrated. Despite the elevated moisture level of the topsoil, due to out-of-season rains, it was possible to delineate the plume which had hardly migrated from its previous position.

Pipeline Rupture and Leakage Indication Along the Pipeline Route.

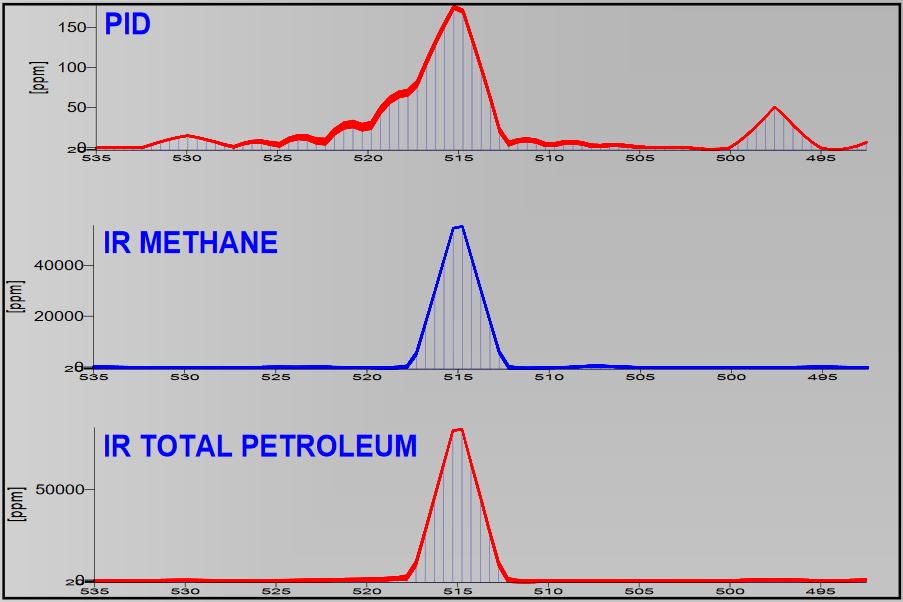

Pipeline leakage found in the open area

This part of the pipeline route is situated in the field, where no industrial activity could cause additional contamination. The graphs on the left represent a 50 meter long section along the pipeline route where older and not very extensive contamination was located. The pipeline rupture and the main leakage are characterized by the position of the peaks. IR Methane reading indicates a long-standing contamination where bacteria have already started production of Methane. IR Total Petroleum channel indicates higher values than on IR Methane channel (TP channel measures hydrocarbon concentration including Methane). This means that hydrocarbon compounds are still presented (or donated) into the polluted site. Presence of hydrocarbons is also indicated by PID channel (PID analyser excludes Methane from reading).

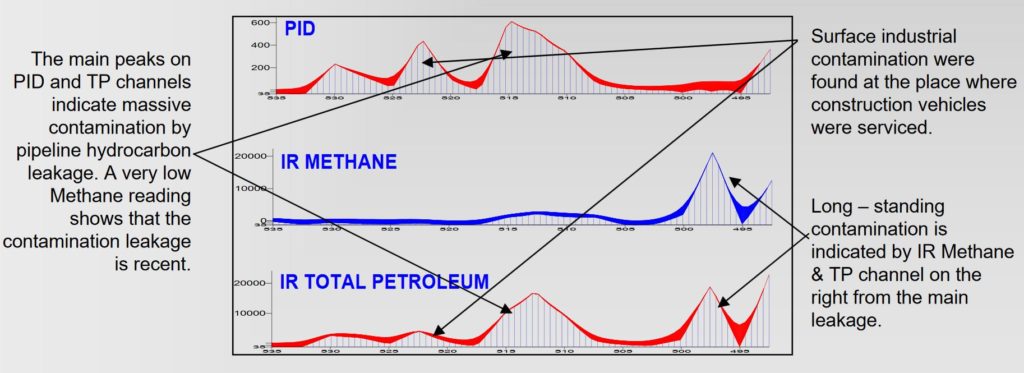

Pipeline leakage found in industrial area

The next surveyed part of the pipeline route is situated inside the industrial area. Pipeline rupture together with additional surface industrial contaminations were indicated and distinguished by the ECOPROBE 5.

Conclusion

Pipeline leakage survey is fast and reliable. The ideal combination of PID and selective IR channels effectively indicates the real leakage and efficiently helps to distinguish between a long-standing and a recent contamination. ECOPROBE 5 is essential not only for leakage location and contaminant delineation, but is also very important in the follow up monitoring of plume migration and the final remediation of the site. ECOPROBE 5 provides inestimable help if bacteria are used for cleaning the site, since ECOPROBE 5 ’s parameters are especially suited for monitoring of bioremediation process (Methane, Hydrocarbon, CO2, O2 channels).