What Photoionisation Detection Is

Photoionisation detection is a measurement technique used to detect and quantify volatile organic compounds (VOCs) and other ionisable gases in the air. Devices based on this principle, commonly called photoionisation detectors (PIDs), are widely used in environmental monitoring, industrial safety, occupational hygiene, and scientific research. This kind of technology is exploited by ECOPROBE by RS DYNAMICS.

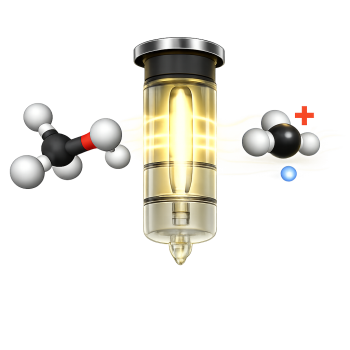

The core idea behind photoionisation detection is that certain gas molecules can be ionised by high-energy ultraviolet (UV) light. When these molecules absorb UV photons with sufficient energy, they lose electrons and form positively charged ions. By measuring the resulting electrical charge, the detector can determine the presence and concentration of specific airborne chemicals.

Unlike combustion-based or chemical-reaction sensors, photoionisation detection is a physical process that does not destroy the sample. This makes PID a fast, sensitive, and repeatable method for gas detection.

How Photoionisation Detection Works

A photoionisation detector typically consists of four main components:

- 1. UV lamp

- 2. Ionisation chamber

- 3. Electrodes

- 4. Signal processing electronics

The process works as follows:

-

1. Air sampling

Ambient air is drawn into the detector, either by diffusion or by a small pump, and enters the ionisation chamber. -

2. UV irradiation

Inside the chamber, the air is exposed to ultraviolet light emitted by a UV lamp. The lamp produces photons with a fixed energy level, commonly in the range of 8.4–11.7 electron volts (eV). -

3. Ionisation of molecules

If a gas molecule has an ionisation potential lower than the energy of the UV photons, it absorbs the energy and becomes ionised. This produces a positively charged ion and a free electron. -

4. Charge collection

The ions and electrons are attracted to oppositely charged electrodes within the chamber. Their movement creates a small electrical current. -

5. Signal conversion

The detector converts this current into an electrical signal proportional to the number of ionised molecules, which is then displayed as a gas concentration (typically in parts per million or parts per billion).

Importantly, gases that have ionisation potentials higher than the UV lamp energy—such as nitrogen, oxygen, and carbon dioxide—are not detected, making the method selective to many hazardous organic compounds.

Who Can Use Photoionisation Detection

Photoionisation detectors are designed to be used by a wide range of professionals, including:

- Environmental scientists measuring air pollution

- Engineers and technicians working with solvents or fuels

- Pressurized tanks personnel monitoring leakages

- Researchers and laboratory personnel studying gas emissions

- Emergency responders identifying chemical hazards

ECOPROBE is portable, handheld, and easy to operate, requiring minimal training for basic use. At the same time, the ECOPROBE can be used by specialists who interpret PID data alongside other analytical techniques.

Where Photoionisation Detection Can Be Used

Photoionisation detection is extremely versatile and can be applied in many settings:

- Industrial facilities (chemical plants, refineries, manufacturing sites)

- Indoor workplaces (laboratories, printing shops, clean rooms)

- Environmental monitoring stations

- Waste management and recycling facilities

- Oil and gas operations

- Confined spaces such as tanks, tunnels, or sewers

- Emergency and disaster response sites

- Research laboratories

Because PID sensors respond rapidly and operate in real time, they are especially valuable in environments where chemical concentrations can change quickly.

Why Photoionisation Detection Was Invented

The invention of ECOPROBE was driven by the need for faster, safer, and more sensitive methods to detect hazardous gases. Traditional detection methods often relied on combustion, chemical reagents, or slow laboratory analysis, which posed several problems:

- Risk of ignition in flammable atmospheres

- Long response times

- Limited sensitivity to low concentrations

- Destructive sampling methods

Photoionisation detection solved many of these issues by providing:

- Non-combustive detection

- Immediate response

- High sensitivity to trace compounds

- Broad detection capability for organic vapours

As industrial processes became more complex and regulations on air quality and worker safety became stricter, PID technology offered a practical solution for continuous and reliable gas monitoring.

Summary

Photoionisation detection is a powerful and widely used technique for detecting ionisable gases, especially volatile organic compounds. By using ultraviolet light to ionise molecules and measuring the resulting electrical charge, PID devices provide fast, sensitive, and non-destructive gas detection. Their versatility, safety, and reliability have made them essential tools in industry, environmental science, health and safety, and emergency response.

Overall, photoionisation detection represents an important technological advancement in our ability to monitor and control chemical exposure, contributing to safer workplaces, cleaner environments, and improved public health.